Manufacturing DPM See it in Action Brief

Manufacturing DPM See it in Action Brief

In the complex landscape of modern manufacturing, the traceability of parts from production to end-use is not just a logistical requirement but a critical component of regulatory compliance, safety, and efficient recall processes. Reliable Direct Part Mark (DPM) scanning technology, especially those provided by Zebra devices, has emerged as a cornerstone solution for achieving comprehensive traceability throughout the product lifecycle. This blog explores how this technology is revolutionizing traceability in manufacturing, ensuring parts are not only trackable but also contributing to broader operational efficiencies and compliance.

The Critical Need for Traceability

Traceability in manufacturing involves the ability to track and document the journey of every part throughout its lifecycle, from raw material to finished product and sometimes even to disposal. This requirement is driven by several factors:

- Regulatory Compliance: Many industries face stringent regulations that require detailed tracking of parts to ensure they meet safety, quality, and environmental standards.

- Public Safety: In sectors like automotive, aerospace, and pharmaceuticals, part failures can pose significant risks to public safety. Traceability allows for quick identification and resolution of potential issues.

- Recall Efficiency: Should a defective part slip through, traceability enables manufacturers to quickly identify and recall affected products, minimizing financial impact and brand damage.

Direct Part Mark Scanning Technology

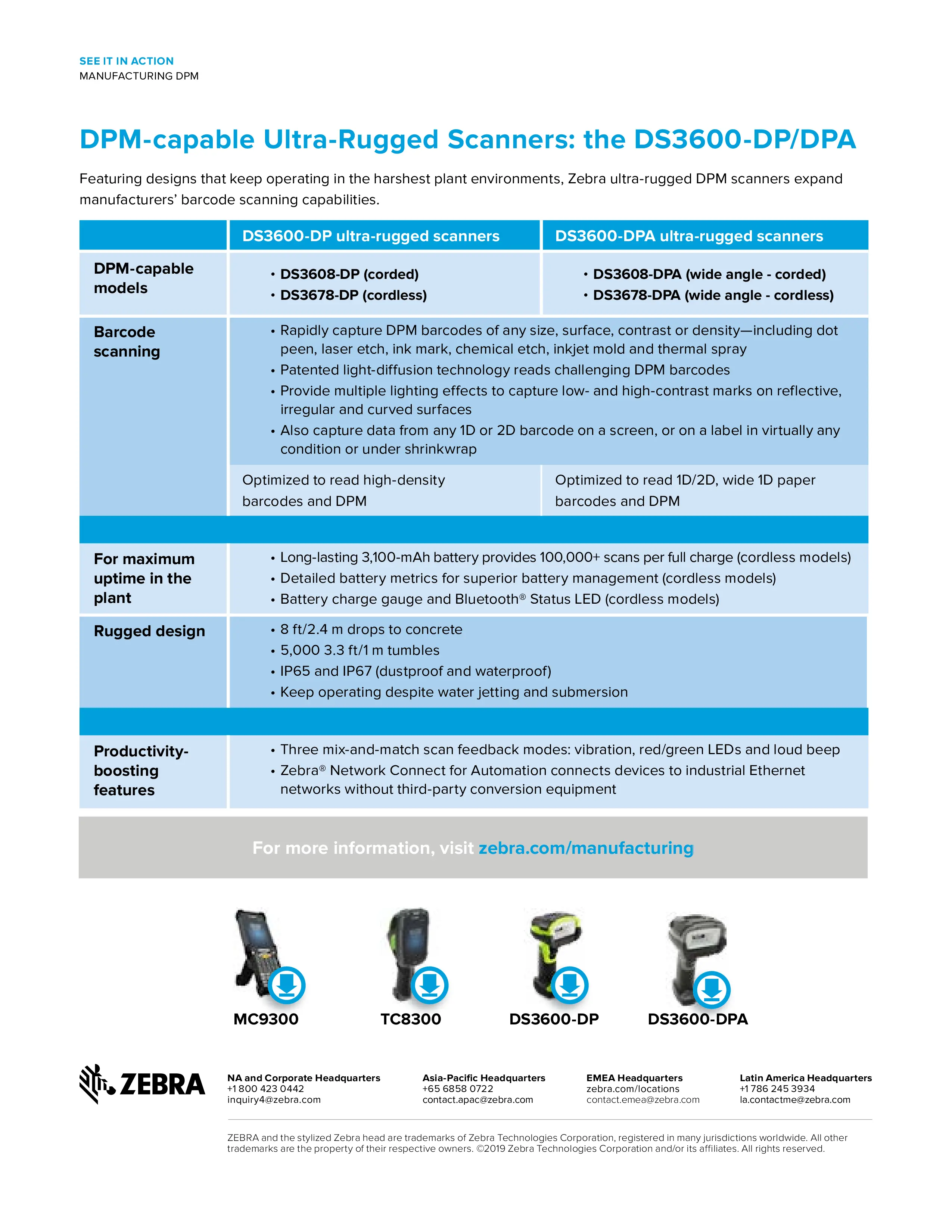

Direct Part Marking involves permanently marking parts with a code—such as a barcode or a QR code—that can withstand manufacturing processes and the lifetime of the part. These codes can be applied through various methods including laser etching, chemical etching, and dot peen, among others. Zebra’s DPM scanners are designed to read these markings reliably, even under challenging conditions, ensuring that each part’s history is easily accessible throughout its use.

How Zebra Enhances Traceability

Zebra’s DPM technology stands out in the market for its robustness and reliability. Here are several ways in which these devices facilitate superior traceability:

- Versatility: Zebra scanners are capable of reading a variety of DPM codes, regardless of the method used or the surface they are marked on. This versatility is crucial in environments like automotive manufacturing, where parts may be made of different materials and subjected to extreme conditions.

- Durability: The scanners are engineered to operate in tough industrial environments, resisting dust, moisture, and extreme temperatures, which ensures that they can reliably track parts throughout the manufacturing process and beyond.

- Integration: Zebra devices easily integrate with existing manufacturing systems and supply chain management software, providing seamless traceability solutions that enhance rather than disrupt existing workflows.

Benefits Beyond Compliance

While compliance and safety are primary drivers of traceability, the benefits of implementing robust DPM scanning technology extend into operational efficiencies:

- Inventory Management: Enhanced traceability provides manufacturers with real-time data on part availability and location, reducing inventory costs and improving production planning.

- Quality Control: By tracking parts throughout the production process, manufacturers can quickly identify and address quality issues, reducing waste and enhancing product quality.

- Customer Satisfaction: Effective traceability ensures that customers receive products that meet all safety and quality standards, which builds trust and satisfaction.

Future of Traceability in Manufacturing

As technology advances, the future of traceability lies in the integration of DPM with emerging technologies such as IoT (Internet of Things) and AI (Artificial Intelligence). This integration will allow for even more detailed data collection and analysis, leading to predictive insights that can further enhance manufacturing efficiency and product quality.

Conclusion

The implementation of Zebra’s reliable Direct Part Mark scanning technology is transforming traceability in manufacturing. It not only meets the increasing demands for regulatory compliance and public safety but also offers significant advantages in terms of operational efficiency and quality control. As manufacturing continues to evolve, the importance of advanced traceability systems like those provided by Zebra will only increase, becoming a fundamental aspect of modern manufacturing practices.

By Pos Qatar

MP7000 Infographic